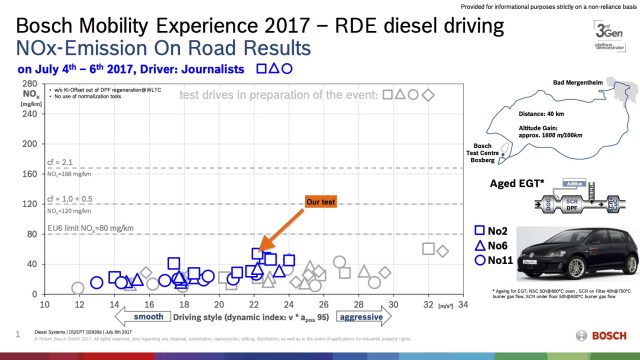

Is there still a future for the diesel engine? According to Bosch, the answer is yes—this week the German company announced it had made a breakthrough by combining a number of existing technologies, which means that modern turbodiesel engines can still make good power and deliver excellent fuel efficiencies. At the same time, Bosch says this combo will emit very low levels of dangerous nitrogen oxides (NOx)—in fact, the company says it can beat future European emissions regulations by 90 percent.

Diesel is a dirty word

For a while, it looked like the turbodiesel engine was an easy way to boost fuel efficiency and cut carbon emissions without sacrificing power or torque. But its dirty secret was that the modern turbodiesels that gained so much marketshare in Europe and were starting to gain popularity here in the US came with some serious baggage. Although they appeared to satisfy EPA and European emissions regulations, it turned out that in many cases that was only because of chicanery. So-called "defeat devices" could tell when a car was being tested, switching engine mapping to beat the test. Out on the open road, a different engine management map would be in charge, resulting in high levels of nitrogen oxide (NOx) pollutants coming out in the exhaust.

Volkswagen Group was the highest-profile offender, and Bosch itself had to cough up $328 million for its part in the scandal. But Fiat Chrysler has been in trouble with US regulators, and, in Europe, Renault, PSA Peugeot-Citroen, Daimler, and BMW have all received unscheduled visits from law enforcement over dodgy engines. The fallout has been far-reaching. In the US, diesel has once again fallen from grace. Volkswagen's reputation suffered a beating, and the company was ordered to pay massive fines and spend even more money building a network of electric car charging stations. The EU even revised its emissions test procedures in an attempt to prevent them from being gamed. And some automakers have even decided to end development of diesel engines.

13mg/km NOx?

Bosch's solution to the NOx problem involves optimizing a number of different steps in the process. Engine displacement is reduced from 2.0L down to 1.7L. The turbocharger has been tweaked to be more responsive, thereby improving transient and low-end torque behavior. Exhaust gas treatment has been enhanced to increase the temperature of the catalyst as quickly as possible upon startup.

Loading comments...

Loading comments...